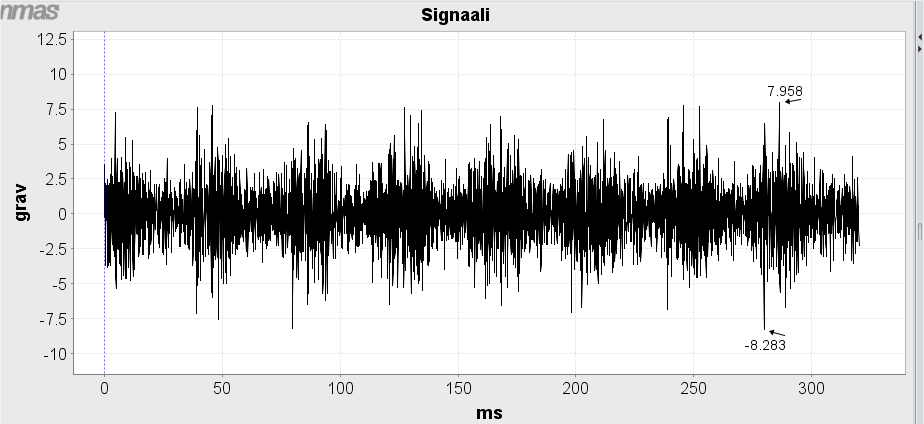

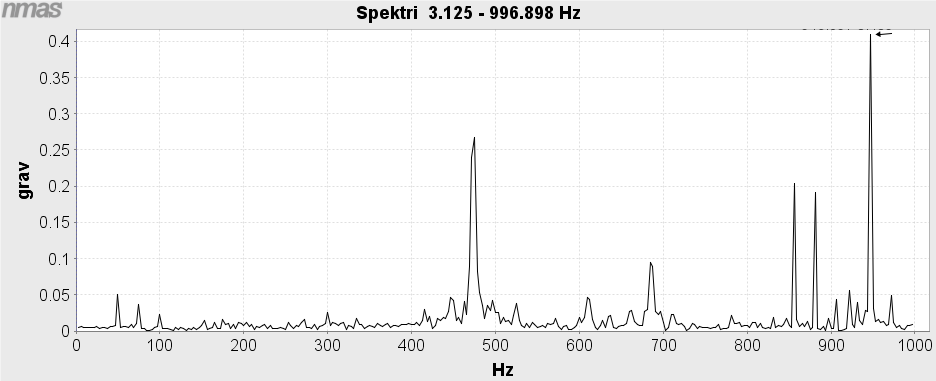

A vibration measurement makes it is possible to get a good understanding of the condition and functioning of rotating machinery. Vibration measurements can be used to determine the machine condition or to establish the state of a machine after completion or overhaul. Also it can observe early damage or disruptions and use troubleshooting when the conditions of the machine are changing.